Global Collaboration, Local Impact: What We Learned in Suzhou, China

When elevator leaders travel halfway around the world, it’s for one reason: to keep the industry moving upward.

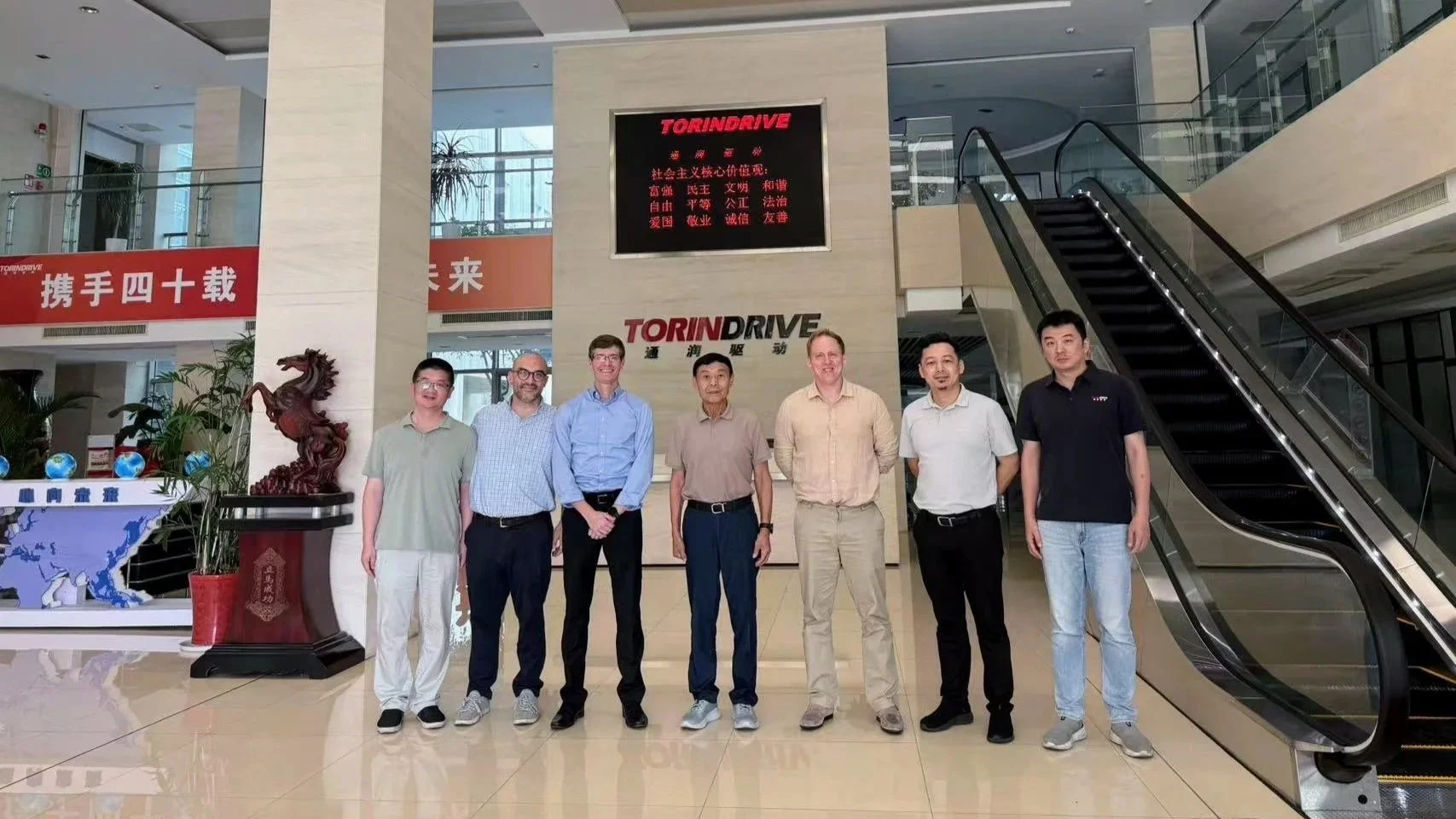

Recently, our leadership team journeyed to Suzhou, China, to visit our strategic partner, Torin Drive - a global innovator in gearless traction machines and elevator components. The trip offered a firsthand look at cutting-edge manufacturing, deepened an already strong partnership, and brought back insights that will directly benefit service teams, mechanics, and building managers here at home.

Left to Right: Wei Zhou, Carlos Escobar, Nick O'Donnell, He Zhang, David Hewitt, Li Zhang, Chao Lu

“Seeing the innovation in action at Torin Drive gave us a renewed sense of what’s possible in our industry, and what’s next for Hyperion.”

Why China, Why Now

China plays a pivotal role in the elevator industry, both in manufacturing capacity and in pushing forward next-generation technology. Torin Drive, based in Suzhou, is recognized worldwide for its precision engineering, reliability, and innovation in gearless traction technology.

With the global supply chain stabilizing and modernization projects accelerating, this visit came at the perfect time to explore new efficiencies, sustainability initiatives, and opportunities to bring even greater reliability to our customers.

Inside Torin Drive - Innovation on Display

Walking the floors of Torin Drive’s manufacturing facility is like stepping into the future of vertical transportation.

We saw:

State-of-the-art production lines with automation that ensures unmatched precision.

Rigorous quality control systems to guarantee product reliability before shipping worldwide.

Prototypes of next-generation machines that promise reduced maintenance requirements and improved efficiency.

From the engineering desks to the final product testing bays, the attention to detail was evident, the kind of craftsmanship that service techs and installers will notice immediately in the field.

The Future of Vertical Transportation – What We Learned

Three big takeaways stood out:

Efficiency is the New Currency – Every process, from production to packaging, is designed to save time for installers and reduce downtime for building managers.

Sustainability is Driving Design – Torin Drive’s latest machines are lighter, use less energy, and are built for longer service life.

Global Partnerships Create Local Impact – Strong supplier relationships translate into faster lead times, better technical support, and consistent parts availability for field teams.

From Factory Floor to Field – The Real Impact for Our Clients

For our customers and partners, these innovations will mean:

Smoother installations with fewer onsite adjustments.

Reduced service calls thanks to higher reliability.

Consistent performance backed by world-class engineering.

Whether you’re a building manager seeking longevity, a consultant specifying high-performance equipment, or a service tech who values easy-to-maintain systems, the advancements coming out of Suzhou are designed with you in mind.

“Partnerships like ours with Torin Drive aren’t just about products, they’re about a shared commitment to pushing the elevator industry forward.”

What This Means for the Industry

Our time in China reinforced one truth: the future of vertical transportation will be shaped by global collaboration and a relentless focus on innovation. As we integrate what we’ve learned into our operations, we’re not just keeping pace, we’re helping lead the way.

Stay tuned for more insights in our upcoming podcast episode, where we’ll share even more from our time on the ground in Suzhou, and how it’s influencing Hyperion’s strategy for 2025 and beyond.