Why the Elevator Industry Runs on Reliability: What’s at Stake When Components Fail

What “Reliable” Really Means on the Job

If you’ve spent any time in the field, you already know: an elevator is only as reliable as its weakest part. Whether you’re running maintenance routes or managing a high-rise, one failing component can shut everything down.

Motors, brakes, seals, valves - they’ve all gotta work, day in and day out, through thousands of cycles. There’s no room for “almost.”

Common Failure Points (and How to Stay Ahead of Them)

Brakes

Dust build-up. Worn linings. Misaligned plungers. You’ve seen it all. One small issue can cause major slippage or worse. That’s why Titan’s retrofit brake kits are built to replace outdated OEM brakes with something safer, stronger, and easier to install.

Seals

If it’s leaking, it’s not working. Downtime adds up fast. Texacone’s seals are built with tight tolerances to reduce installation issues and stay leak-free longer, even in the toughest conditions.

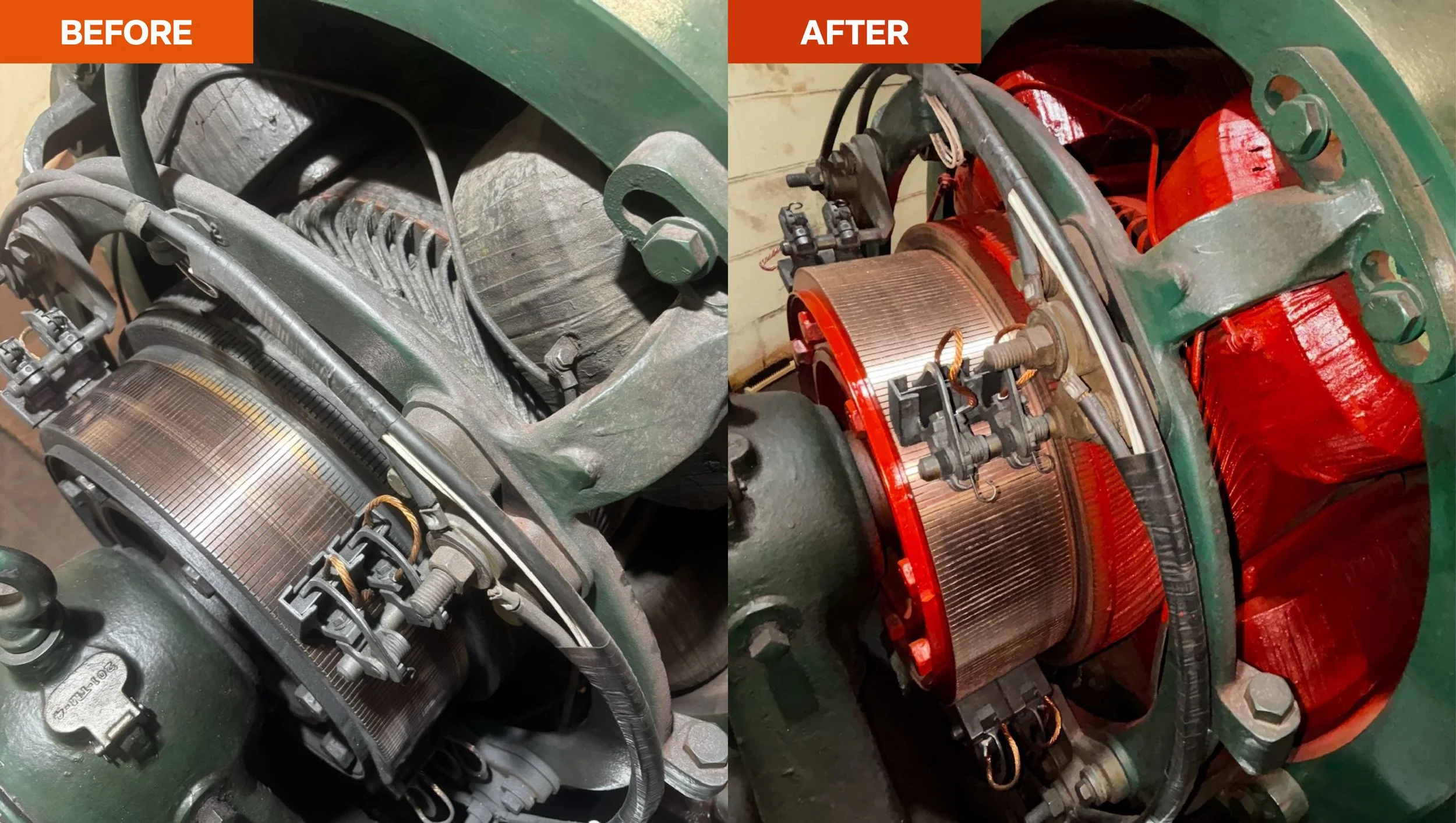

Motors

When it comes to drive systems, TorinDrive motors are workhorses. High-load reliability, built-in thermal protection, heavy-duty insulation, these things are designed to take a beating and keep moving.

Why It’s About More Than Just Specs

Sure, data sheets matter. But in the field, reliability is about trust. When you're on a job and under pressure, you need to know the part you're using will fit right, work right, and hold up over time. That’s what we aim for across every Hyperion brand.

Need More Uptime and Fewer Callbacks?

We’ve got you covered. Check out the Hyperion Solution’s family of brands today.